As an intern at a quadruped robotics company, I worked on many design projects for testing, research, and additional hardware. I also helped with assembly, repairs, and cycling before the robots were shipped. Some of the notable projects that I worked on and can share were:

Lawn Mower

This project aimed to develop a fixture so the quadruped robot could pull a payload on wheels. The test payload was a push mower that I modified so it would cut while being pulled. My approach to this project was to develop an attachment that would connect to existing threaded holes on the robot and have enough strength and range of motion to allow for turns and movement on various inclines. I was limited to 3D printing the prototype, which was challenging because the component had to be very strong in case the lawn mower got stuck in unpredictable grass.

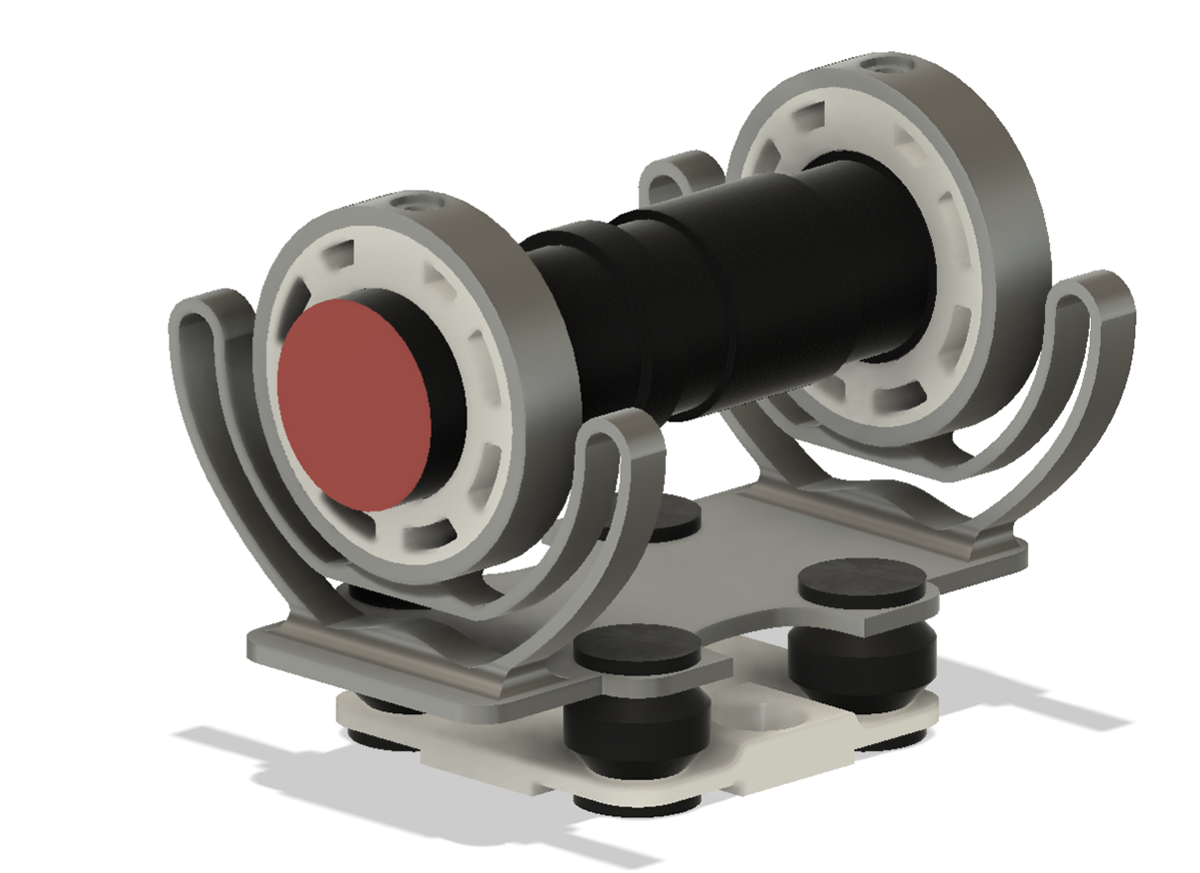

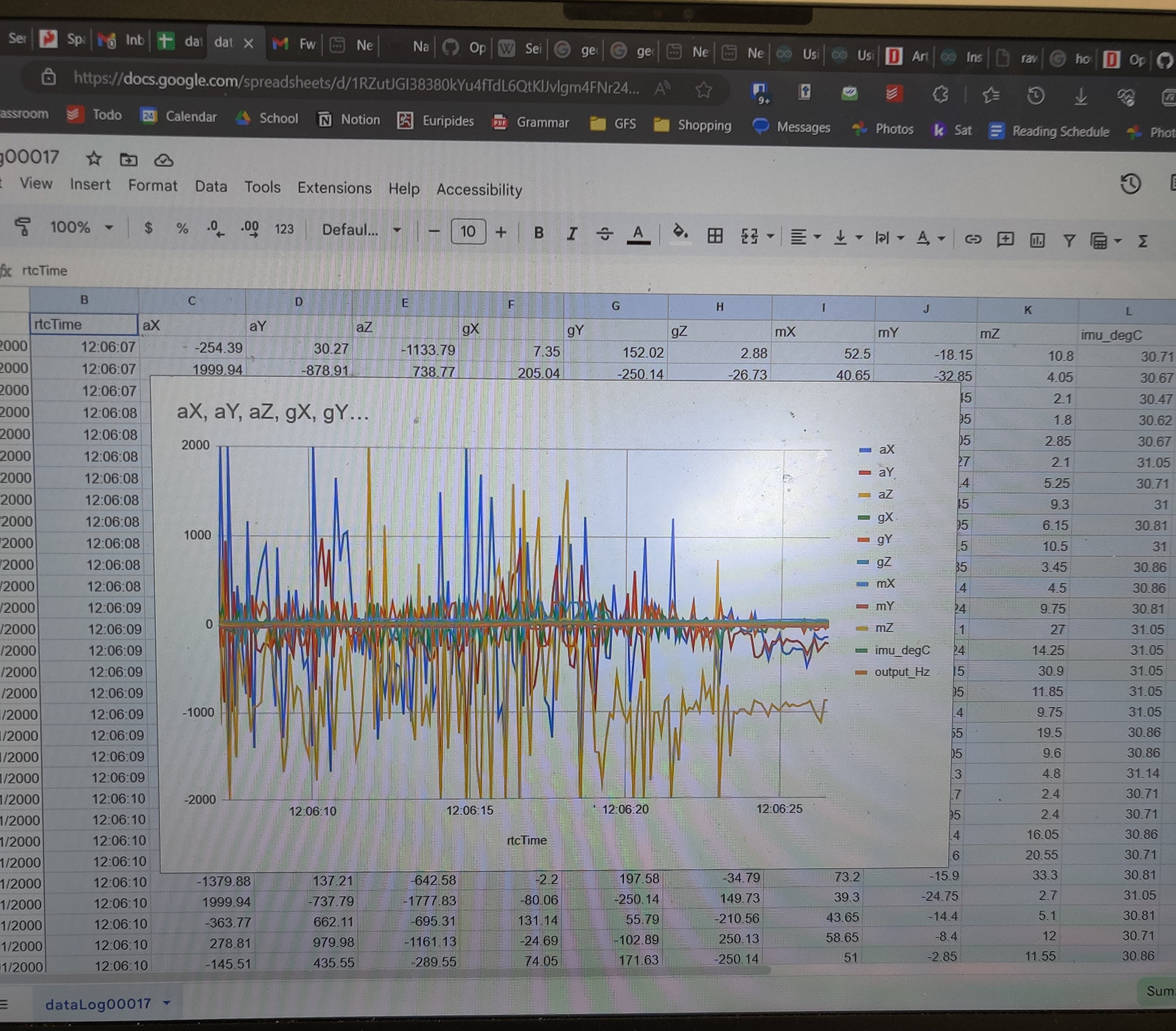

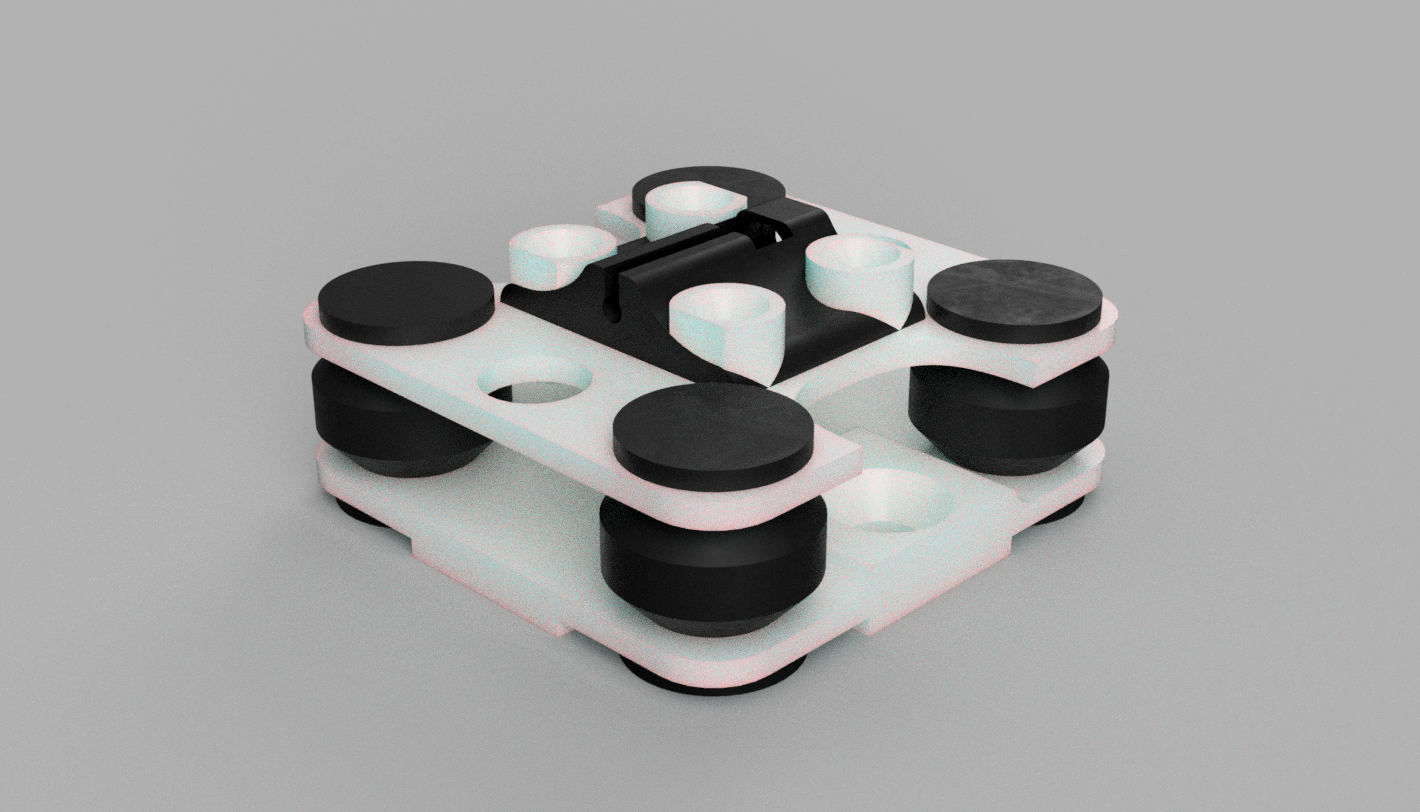

Microphone payload

The goal of this project was to design a microphone attachment that could record sound more clearly than the built-in microphone, which was susceptible to vibrations from the robot. Over the summer, I tried many different microphones and mounts and researched which methods resulted in the clearest audio. I also did experiments using AI to filter the sounds of the robot, and used an accelerometer to map the vibrations of the robot, with the idea that software could cancel them out. There were two designs that came out on top: One was a compact mount for a Lavalier microphone that was 3D printed out of semi-flexible plastic and had rubber bumpers; this method worked because it was not heavy and could mount to the top surface of the robot and create isolation. Its vibration-minimizing materials also worked very well. The other system was a parabolic microphone mounted to a custom shock-absorbing mount. This design worked well because the microphone is designed to capture audio from 20-30 feet away from it. However, it was very large and would break if the robot tumbled or rolled over.

Handle

This project aimed to improve the webbed canvas handles that shipped with the robots. The redesign was an aluminum handle that had the added functionality as a roll bar. Having a roll bar prevents the attenas from being bent at too harsh of an angle. I made many 3D printed iterations to hone down the ideal height and ergonomics of the handle. Then, I refined the model further so it would be easy to manufacture in aluminum.

Traction Spikes for Icy Environments

This project was to develop spikes that could attach to existing custom-made soles for the robot. This version was 3d printed on the ONYX Markforge printer, but designed to be made out of bent sheet metal. We tested the impact of metal spikes on the Penn Ice rink and found that they help a lot with traction and running speed/consistency when the robot is on a slippery surface. This prototype screws into metal threaded inserts, so it can be easily removed.